3D Printers: Difference between revisions

No edit summary |

|||

| (4 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

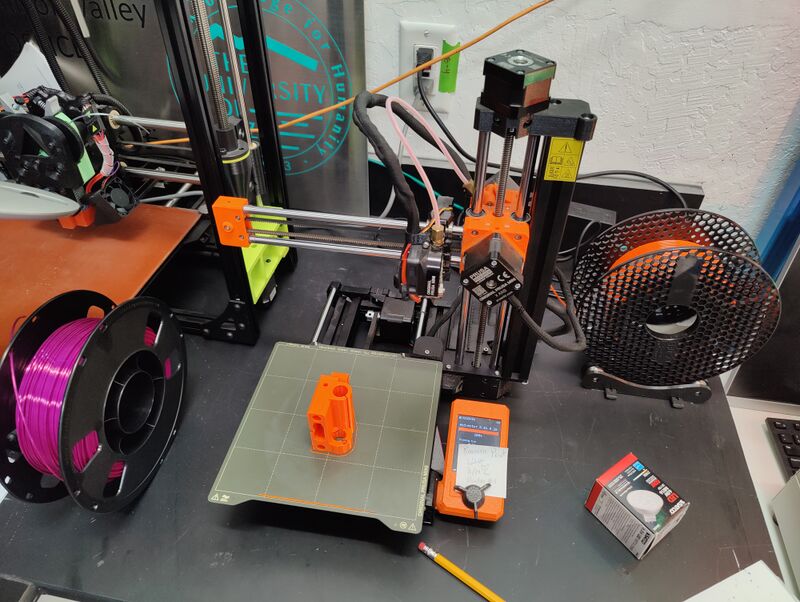

[[File:PRUSA MINI Printed MK3S Replacement Part.jpg|800px]] | |||

We have 3 3D printers in the makerspace. While 3D printers can be used in a variety of ways, we have some policies to keep our printers functioning well. | We have 3 3D printers in the makerspace. While 3D printers can be used in a variety of ways, we have some policies to keep our printers functioning well. | ||

| Line 36: | Line 38: | ||

* clam knife | * clam knife | ||

* if you need it: Purple, washable Elmer's glue stick | * if you need it: Purple, washable Elmer's glue stick | ||

[[File:3D Prints and Electronics Lab Projects Shelf.jpg|800px]] | |||

[[File:3D Print BambuLabs X1 Espresso Tamper.jpg|800px]] | |||

[[File:3D Print Replacement Shelving Foot.jpg|800px]] | |||

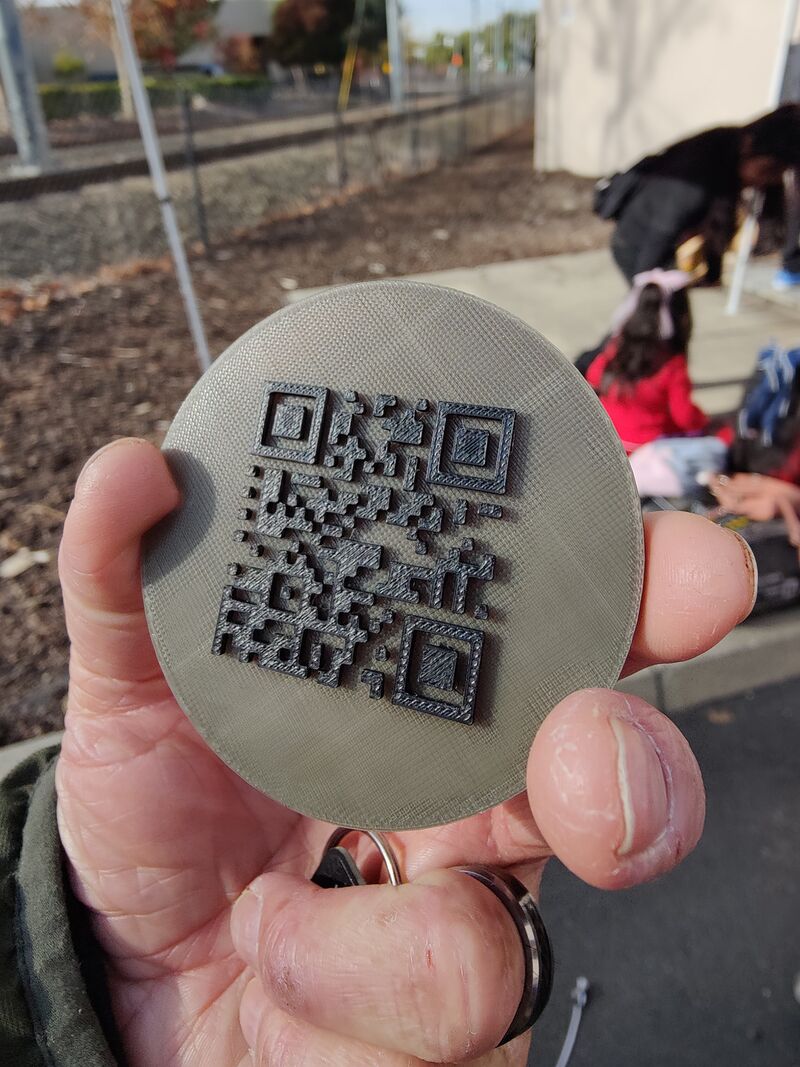

[[File:Andre 3D Print Heat Color Change QR Code Puck.jpg|800px]] | |||

[[File:Andre 3D Print Heat Color Change Hacker Dojo Logo Puck.jpg|800px]] | |||

== PRUSA == | == PRUSA == | ||

| Line 47: | Line 62: | ||

Updated to last firmware, tested and calibrated April 2024 | Updated to last firmware, tested and calibrated April 2024 | ||

Updated to v6.0.4 firmware, tested and calibrated August 2024 | |||

UNKNOWN firmware updated to incompatible version. BRICKED | |||

UN-BRICKED; Updated to v6.1.2 firmware, tested verified calibration October 2024 | |||

=== Original Prusa i3 MK3S === | === Original Prusa i3 MK3S === | ||

| Line 56: | Line 76: | ||

Updated to latest firmware, tested and calibrated April 2024 | Updated to latest firmware, tested and calibrated April 2024 | ||

Updated to 3.14.0 firmware, tested and calibrated August 2024 | |||

Ready for upgrade, printing is so so even with newer filament | |||

Seems to have been abused a bit with really high temperature filaments and bed temps | |||

Spells like toxic and burned bits coming out, mostly functional, still some consistency issues | |||

[[User:Do'h|Do'h]] ([[User talk:Do'h|talk]]) 20:51, 11 October 2024 (PDT) | |||

=== Original Prusa i3, upgraded to MK3S === | === Original Prusa i3, upgraded to MK3S === | ||

Latest revision as of 10:58, 12 December 2024

We have 3 3D printers in the makerspace. While 3D printers can be used in a variety of ways, we have some policies to keep our printers functioning well.

Filament

Your filament should be kept clean and dry. Dust and dirt on the filament will clog the hot print head and cause your print to fail.

PLA and ABS

Recommended for new users. The 3D printers can use other materials, but they each introduce some complexity to the print process. Until you are very familiar with 3D printing and how other materials affect the printing, use PLA and ABS.

- PLA easily absorbs water from the environment. PLA should be stored in a sealed plastic zip lock bag and you should add desiccant packages inside the bag.

- Never use glue on the bed with PLA or ABS.

- Never run PLA above 230C. Higher temperatures cause PLA to carbonize and permanently clog the print head.

- Do not let PLA sit in an idle hot print head for more than three minutes. Even at the specified working temperature PLA will carbonize and permanently clog the print head. (For instance, don't start the printer to heat up and then go out to get a cup of coffee.)

PET-G

A good material when you are ready to move up.

- PET-G comes in a variety of specific materials that offer more dimensional stability.

- PET-G requires the use of glue on the bed. The glue is NOT for adhesion. Rather, the glue is used to prevent the part from sticking to the bed and ruining it. If you don't use glue with PET-G you will ruin the print bed.

- Use a purple, washable Elmer's glue stick. Put on just a very, very, very think coat of the glue.

- Put the glue on while the bed is cool.

- Put the glue over a large part of the bed, but not near the corners.

- After you print one part you can position your print to a portion of the bed that has been glued, but has not been printed on yet.

TPU

- You MUST use glue for release with TPU.

Strength

There are different aspects to "strength", and no material wins in all categories. PLA is rigid, but that can make it brittle, so PLA is seldom the choice for parts needing strength. ABS has long been the choice for functional parts. The printed parts of the Lulzbot are made of ABS. So is Lego. But ABS warps, which is a problem on bigger prints. Nylon and polycarbonate have some great characteristics, but they are tricky to work with, and they aggressively absorb moisture from the air, so you have to keep baking your filament to dry it out. Scroll back to July 18 for some discussion of PC-MAX, a brand of polycarbonate. PET-G is really a wide range of materials, with a wide range of properties. I like ColorFab-HT, although it prints at high temperature, making warpage more of an issue. Most PET-G doesn't warp much at all. A lot of people rave about Innova-1800, although I always had a hard time getting it to stick to the bed. nGen is an easy-to-use PET-G. All of these can be used on the Lulzbot.

3D Toolkit

Consider making up your own 3D printer toolkit.

- hex wrenches

- putty knife

- long tweezers

- non-scratching, lint free wipes

- 30% isopropanol and water

- clam knife

- if you need it: Purple, washable Elmer's glue stick

PRUSA

Original Prusa MINI

1.75mm Filament, 0.4mm Nozzle

Smooth heated print bed

Updated to last firmware, tested and calibrated April 2024

Updated to v6.0.4 firmware, tested and calibrated August 2024

UNKNOWN firmware updated to incompatible version. BRICKED

UN-BRICKED; Updated to v6.1.2 firmware, tested verified calibration October 2024

Original Prusa i3 MK3S

1.75mm Filament, 0.4mm Nozzle

Smooth heated print bed

Updated to latest firmware, tested and calibrated April 2024

Updated to 3.14.0 firmware, tested and calibrated August 2024

Ready for upgrade, printing is so so even with newer filament Seems to have been abused a bit with really high temperature filaments and bed temps Spells like toxic and burned bits coming out, mostly functional, still some consistency issues Do'h (talk) 20:51, 11 October 2024 (PDT)

Original Prusa i3, upgraded to MK3S

1.75mm Filament, 0.6mm Nozzle

Textured bed, adhesion sometimes inconsistent.

Updated to latest firmware, tested and calibrated April 2024

TAZ

The carriage frame of the TAZ must be square for the printer to work well. The TAZ should NOT be moved around the shop. Every time you move it you risk tweaking the frame. Leave the TAZ where it is!

The TAZ has a heated bed. The bed is easily scratched and damaged. Do not pull your part off the bed. Do not gouge at the bed. A new bed costs $150.

- Design

- You should print a skirt to 3, especially for small parts

- Start up

- While the bed is cool use the 30% alcohol solution and a paper towel to clean the bed of any residue from the previous user.

- Also clean the leveling spots on the four corners of the bed.

- Heat the nozzle to 200C

- When hot,

- Pull the old filament from the print head

- Insert your filament into the head.

- Purge the print head by running filament. Don't be afraid of wasting filament, this is an important step.

- Operation

- As printing starts, watch the head and remove the "booger" of filament that forms before the actual printing starts. This will give you a cleaner start to your print.

- Part release

- Let the bed cool completely before releasing your part.

- Use the clam knife to GENTLY lift the skirt from around your part.

- Now use the putty knife

- Place the putty knife flat on the bed with the edge of the blade against the edge of your part.

- Rap the end of the putty knife with a small hammer. A tap is all it takes and your part will pop off.

- DO NOT pry your part from the bed. This will delaminate the bed and ruin it.

- Shutdown

- Do not pull your filament from the hot head. The head has probably cooled by now and you risk breaking off your filament in the print head.

- Instead, snip off your filament outside of the print head, leaving two inches of filament.

- When the bed is cool, use a damp paper towel to wipe off the bed. If you used glue, wipe until no more purple is seen on your towel.

LULZBOT TAZ 6

Currently parked in Laser Lab. Has 1.75mm and 2.85mm extruder?

LULZBOT TAZ 6 (Dual Extruder)

Configured with dual 1.75mm extruders. Currently being tested and configured in Electronics Lab.

Has 1.75mm and 2.85mm dual extruders, and single extruder.

Cura LE loaded on Mac workstation. For working with dual filaments, select the models and use the Merge Models then slice.

Makerbot

Legacy printer, none of this type currently at Hacker Dojo